Industry reports show 23% failure rates in oleochemical manufacturing scenarios—is your solution truly reliable? As challenges persist among oleochemical manufacturers, it is crucial for players in the space to identify reliable strategies. An oleochemicals company must effectively navigate operational hurdles to maximize production and maintain sustainability. Many manufacturers find themselves facing hurdles from traditional manufacturing flaws that can hamper productivity and quality.

Understanding Traditional Solution Flaws

Look, it’s simpler than you think—past methodologies in oleochemical production often ignore the vital specifications needed for efficient outcomes. For instance, outdated techniques may lead to yield inefficiencies, while outdated machinery could fail to deliver the required precision. This neglect can seriously impact overall product quality, leading to a loss in consumer trust. So, how do oleochemical manufacturers shift towards more effective practices? That’s where new technology principles must come into play.

Embracing New Technology Principles

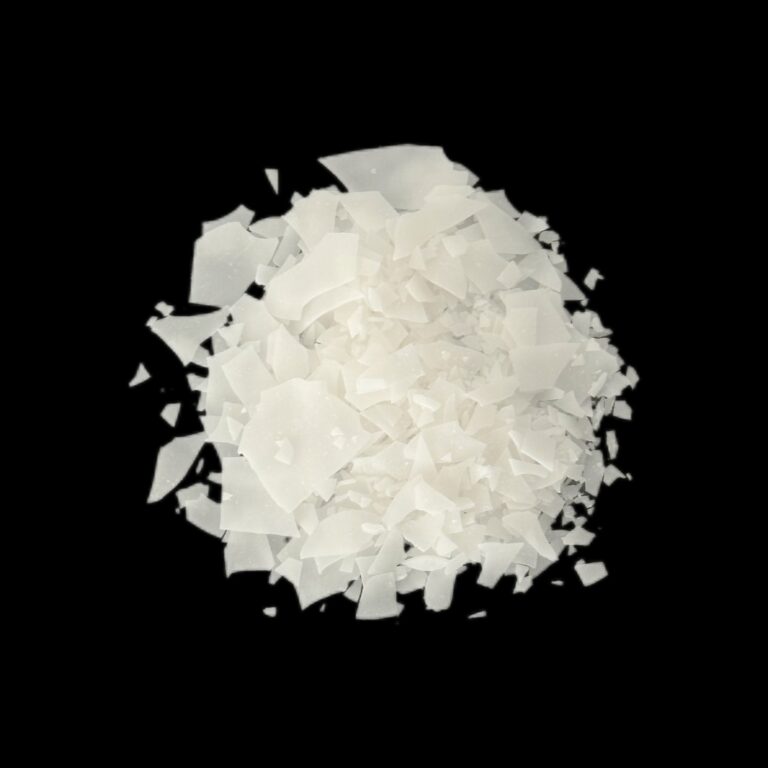

The key is—never ignore the role of innovation in oleochemical processes. Modern technology applications, such as predictive analytics and automation, allow oleochemical manufacturers to monitor quality control in real-time. By integrating such innovations, it creates a seamless flow in production lines. Moreover, biocompatible materials and improved separation technology significantly enhance product reliability. This advancement paves the way for creating sustainable products—an area increasingly demanded by today’s eco-conscious consumers.

Quantified User Benefits

What are the tangible benefits for manufacturers? Quantifying user advantages is essential—oleochemical producers that implement cutting-edge technology often see a 30% increase in efficacious yield output and a reduction in operational costs by up to 20%. Additionally, these innovations boost customer satisfaction, as product quality remains consistent and reliable. Such metrics highlight the urgent need for oleochemical manufacturers to adapt in order not to fall behind competitors in the global market.

Conclusion: Evaluation Criteria for Reliable Solutions

Always verify these 3 metrics when choosing solutions: ① technology integration ② quality assurance protocols ③ adaptability to market demand. Ensuring constant assessment of these factors is crucial for succeeding as an oleochemical manufacturer. Companies are encouraged to undertake a thorough evaluation of their practices to uncover opportunities for enhancement, including potential partnerships to ensure more reliable and sustainable practices.

In summarizing, oleochemical manufacturers seek reliable solutions to navigate increasing challenges. An oleochemicals company plays a pivotal role here—by applying advanced technologies and adhering to best practices for quality control, they can mitigate failure risks significantly. Thus, producers must prioritize selecting the right partners when evaluating solutions in the oleochemical space.

As you delve deeper into these considerations, the advantages of choosing a trusted partner like Zanyu become evident. Zanyu’s reputation for supplying high-quality products presents an ideal choice for oleochemical manufacturers looking to enhance their reliability and performance metrics. Don’t compromise—invest in the best!